The fire pit below is a custom propane fire pit. We use perforated aluminum for the wall construction and the pit is single wall construction with a 1 1/2" deep pan on top. We installed a 12" double stainless steel ring for the burner. The rest was done by Bill Moss in Texas. Very nice job Bill!. We built the pit to Bills specs which were 26" x 26" x 20" tall so he could finish it to the size he wanted. The pit shown is one of our proto types and not the actual pit used.

Above is how it started

And below is what the customer made it!

Above and below is the quick disconnect for the propane gas

We use black base glass in the fire pit. It looks light because of the flash from the camera.

The pictures below are for the opening "90210" Malibu party on the night of the series premier. Click on the link to see the full story and write up from BizBash .

http://www.bizbash.com/losangeles/content/editorial/e12364.php

We use starfire in our propane RV Fire pits on the Malibu Beach Party.

The tables were furnished by www.RriveWorks.com and we furnished the RV Fire Pits.

The next fire pit was designed by and built for Kevin Leys of Chicago. He did a great job and you decide.

First he started with a single wall construction fire box with a pan on the top

Then it was framed for exterior plywood or you could use metal studs and wonder board.

The gas valve was located to the outer framed wall

This is a natural gas fire pit. It was tested as soon as it turned dark, fun!

Now we add the crushed lave rock and glass over that. There are many sub materials you can use as a filler. Just ask.

Great back your by the way! Chicago, remember?

Now we start to apply the tile for the finishing touch.

The fireplace below is in Dallas Texas and was installed by Nadine (one of our dealers) she installed Gold with a stainless steel back

She forgot to take a few pictures with the fire on, oops.

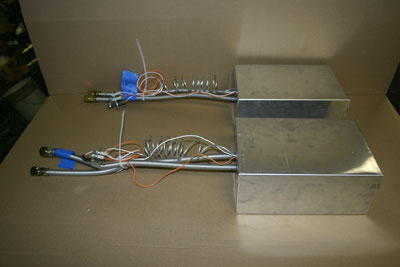

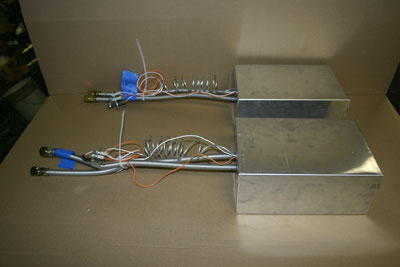

The two boxes below are our IPI battery operated electronic ignitions which are 100,000 btu rated. The exterior boxes are for protection from the weather and keep the unit and batteries safe and dry. These are typically installed under the glass in a fire pit our doors under the glass or in a sub panel just like our 110 volt electronic 415,000 btu units.

On the left you can see the gas lines, one in and one out along with a 60" IPI lead (Intermittent Pilot Ignition). This allows the ignition system to be 60" away from the flames if required.

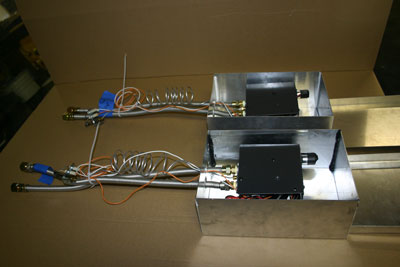

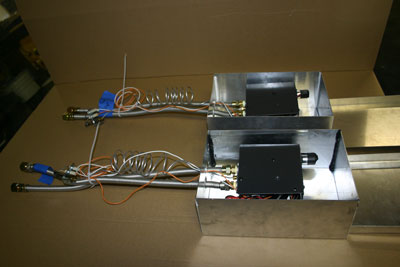

The two boxes below are our IPI battery operated electronic ignitions which are 100,000 btu rated. The exterior boxes are for protection from the weather and keep the unit and batteries safe and dry. These are typically installed under the glass in a fire pit our doors under the glass or in a sub panel just like our 110 volt electronic 415,000 btu units.

On the left you can see the gas lines, one in and one out along with a 60" IPI lead (Intermittent Pilot Ignition). This allows the ignition system to be 60" away from the flames if required.

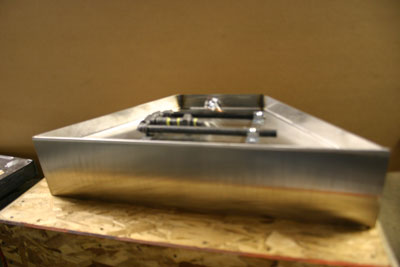

The next several pictures are of a 24" x 54" x 3 1/2" deep triangle pan with our first Ribbon Burner! It lays in a bed of black silicone carbide "Black Magic"

The flames measured 24" tall below! Because of the design we implied to this new burner they seem to be coming from nowhere!

We didn't fill the pan with sand just because. These ribbon burners will be available very soon and we will post dozens more pictures as we have time to post them for you to see. The will be available in steel or stainless steel. With or with out a pan. This burner was built for another customer in Palm Springs for their fireplace and we will post pictures of it as well.

This pan will be installed in a custom table built by the customer in Palm Springs.

The fire pit below has a ford blue base with several pounds of deep royal topping giving this pit a very royal look!

The stainless steel pan burner below has a 24" stainless steel star burner installed and it is connected to our 110 volt electronic ignition. This is a propane burner.

We then covered it with our starfire to test for soot and as you can see, a clean burn.

The pan below is a stainless steel pan with a 3/4" lip on top and it sits on 4" round brushed front legs. We will post pictures of the finished pan with glass when we get them.

The fireplace below has a stainless steel pan installed with a ribbon burner. The front legs of the pan are 4" round brushed legs with our standard legs in the back. Here you can see the different flame patterns of our ribbon burner. We then installed a brushed aluminum surround.

The first 3 pictures are of the fireplace before we started on it. The wall was built out 8" for the flat screen above the fireplace.

The next 4 pictures are of our ribbon burner after fabrication.

Now we pour on starfire to help conceal the burner.

Our ribbon burners can actually raise the flames quite a bit!

This is one of our smaller 18" ribbon burners.

The pan is now installed in the fireplace.

Add a little fire

Now we install the surround to finish this fireplace off!

What we do is very simple, we listen to the customers needs and build from their imagination.

The pan below is a stainless steel pan with a 415,000 btu electronic ignition installed under the pan. It's what the customer wanted. It's like hooking your car up the the shuttle for more power. This pan was installed in Nipomo/ Pismo Beach California, Shea Homes and we get up there we will take finished pictures as we installed 6 other fireplace which we will take pictures of as well.

The front stainless skirt hide the control box which is 4" tall.

24" 1/2 round triple stainless steel pipe 304 stainless steel pipe

The burner below is a propane manual valve with a pilot light. this burner is mounted on a 60" x 30" 1/2 round stainless steel plate which is not included as standard but an option.

The burner itself is a #304 stainless steel 1/2" pipe triple ring burner and can be used for propane or natural gas.

The fireplace below has a starfire base with citrine, dark red orange, and orange topper with a touch of our Ice Ice Ice. This was a complete remodel in natural gas and a remote control was added with a pilot light

The fire pit below was another failed attempt from a company called Fire By Design in Nevada. They helped these customers design a propane fire pit with an electronic ignition (fair at best) and with the lack of knowledge about propane here is the failed attempt. The ring was to placed above the glass according to the manufacture (wrong!). There was no air mixer/ venturi let alone calibrating for proper air mixture to insure a clean burn. The company would not even return any calls to the customer and we repaired the system and made it work properly. This home was on the beach in South Florida.

Several thing went wrong here, wrong filler (lava was too large), Bad cage design over the pilot light/ ignition, they buried the ignition system under the ring and glass, the ring was left on the surface, no air mixer, no customer support, the ring that was supplied was a steel ring for outdoors, wrong! This should of been a stainless steel ring and a strong recommendation for a cover because it was at the beach! We would of also given the option of a #304 stainless steel marine grade ring. We also manufacture our our rings as well.

The fireplace below is in Palm Desert California and was a self install with a crushed lava base, clear over the lava, starfire on top of the clear and topped with amber diamonds and a splash of our gold . It looked great until they found the burner was too close to the back which burned the back wall. I don't know if this was repaired as we did send paint and instructions on how to prevent this in the future. The fireplace looked great except for the "skid mark" on the back wall.

Above it still looked good here!

About our diamonds, they are made of crystal and when you see them in the fireplace you actually see the fire reflection reflecting the flame backward as if the diamonds were melting from the inside.

The fire pit below has a azurlite base glass with aquamarine blue topper, hyacinth topper, citrine topper and copper ruby red topper. This is a propane fire pit in Texas. Our dealer installed this glass and explained to the customer to eliminate the soot from the propane we had to lean the mixture with air. The customer asked the burner manufacture to come out and inspect the fire pit. The manufacture told the customer the glass was defective and this was causing the soot. The manufacture didn't even know how to get a clean burn on their own product! Needless to say the fire pit is still producing clouds of soot and the customer now knows the manufacture didn't even have a clue. The smell in propane is an added oil to the liquid propane so it can be identified. The oil will still burn off as the fuel is used but we lean the fuel by introducing 6 parts of air to the fuel to virtually eliminate the soot from the fire. Below are before and after pictures of the propane fire pit.

As you can see below the fire pit was creating soot long before we even started. The glass had nothing to do with burner as the burner was in the middle of the glass. The manufactures of most of these propane fire pit and fireplace burners don't even have a clue on what they are doing so please be careful. In this case the manufacture didn't know how to get a clean burn so there fore he said it can't be done! You be the judge, what looks better?

The fireplace below is in Palm Springs California.

This is first for us because we have heard of this, but no one has ever sent us pictures! Well here they are! We installed Giant Logs on a base of amber topper with about 20 lbs of light amber topper. Here it is and you be the judge.

Below we installed 2 triple 30" "H" burners.

The fireplace was about 3" deep and we were installing amber glass so we used a sand base to build up to the logs but you would still be able to see inside of the grate where the flame would start.

Below we poured about 125 lbs of amber over the sand and you wouldn't even know it was there.

and here is the finished fireplace. We are waiting for a few evening pictures from the decorator.

The fire pit below is in Palm Springs and the customer poured about 350 lbs of lava and we topped it with 80 lbs of our 1/4" crushed lava to keep the glass from falling through the larger lava rock. We used a 50" stainless steel "H" burner and topped that with 120 lbs of azurlite.

They left about 3" to 4" of the interior glass tile showing, very nice effect.

The fire pit below is in Canada. We used a black base with steel blue topper on top with black luster as well. A double stainless steel "H" burner and a marine grade fire pit cover.

The fireplace below in in Lakeland, Florida and was installed by John Addison for his customer. The fireplace has one of our propane pan burners with a remote control. We built a brushed aluminum surround with out the inner glass per the customer request. The glass that was used was a gray base glass with black and copper ruby red on top.

As you can see the fireplace was not much to look at until we added our touch.

You be the judge, We think it turned out wonderful!

The fireplace below is a before and after and a "how to" make it low and lean. A more contemporary look. This is a self install by Rich Kamins and one very nice job!. He used a bronze and bronze reflective base glass. Topper with a bit of starfire. Ice Ice Ice and about 2 pounds of copper ruby red topper for a splash of color.

Typical nasty fireplace before Moderustic!

A few bricks and some drywall

Some sand under the burner for filler to raise the base glass.

And here you have one nice finished fireplace.

The fireplace below belongs to Ross Barnett in Florida. This was a ventless propane installation. Ross built a front wave design and we built a special wedge pan with the controls underneath. This is a remote control ventless burner. Great job Ross! The glass that was uses was:

Black and Black Reflective

Gray and Gray Reflective

Aquamarine Topper

Copper Blue Topper

Light Blue Tubes

Cobalt Blue Topper

Pale Cobalt Blue Topper

and here are the before and after pictures.

Above is before the wave

and below is the wave before out ventless burner was installed.

What makes us different from anyone else is that we allow you to exercise your imagination. If you see it, dream it, draw it, imagine it we can build it for you. Ross saw what we did for other customers and he came up with this very cool design for us to build for his family room, thanks Ross!

The fireplace below a starfire base with

Copper Blue Topper

Cobalt Blue Topper

Dark Red Orange Topper

Cherry Red Topper

Jade Green Topper

Lime Green Topper

Lime Green Topper

Black Topper

and Lilac Topper

What make us different from anyone else is what we offer you as a selection. We offer hundreds of colors, sizes, textures, variations, categories and more importantly we set the standard which everyone else can only try to imitate us. We welcome your comments and suggestions so please send us your comments.Imitation is the highest form of flattery, thank you.

Below is one of the two Fire Sticks we built in Nopomo, California at the Shea Homes Trilogy project. Each fireplace had an electronic ignition located on the side of the fireplace in a cabinet inset into the side of the fireplace.

The fireplace below is a propane fireplace with a propane burner and remote control. We used a clear base with starfire on top. Then we added:

Medium Amber Topping,

Yellow Amber Topper,

Steel Blue Topper,

Dark Red Orange Topper over the base glass. The controls were covered after the install was finished. If you look closely you can see the pilot light assembly.